Dowel

Laminated Timber

In this project, we developed Dowel Laminated Timber (DLT) as a sustainable alternative to Cross Laminated Timber (CLT), using dehydrated hardwood dowels instead of glue to laminate the timber. Once placed in the pre-drilled holes, the dowels slowly expanded as they rehumidified, creating a strong and durable connection. A CNC machine, guided by a custom-built DLT jig, ensured precise positioning and angling of the dowel holes. This approach eliminated the need for unsustainable glue, resulting in the first DLT-based mobile structure and offering a recyclable, eco-friendly solution for architectural design.

Mycelium and Bioplastic

I researched the use of bioplastics mixed with nutrients and mycelium spores. I wanted to find out how this plastic could direct the growth. It also allows for molding the substrate into different shapes, where the plastic is slowly eaten by and replaced with mycelium while keeping the shape. Finally, I researched using bioplastic as glue to connect alive mycelium panels. That allows building large, single-piece and alive structures, as the glue is replaced by mycelium, thus connecting the mycelium panels to each other. Alive structures that have the potential to regenerate.

EDIBLE

TABLEWARE

During my time working in the lab at Mediamatic Amsterdam, I researched and developed edible tableware. These plates and bowls, crafted from mycelium, offer a sustainable alternative to disposable products. They can be dried and stored for takeaway foods or freshly prepared and served in a restaurant. This edible design demonstrates how mycelium can merge utility and sustainability, providing a zero-waste solution to modern dining.

Resin Research

Local pine resin was collected and carefully processed to test its protective and adhesive properties. The resin was heated to remove impurities and cleaned, with the turpentines extracted during the process. A portion of the refined resin was mixed with small amounts of linseed oil and glycerin, resulting in a waterproof varnish or coating ideal for protecting surfaces. Another portion of the resin was combined with ashes to create an adhesive, with various proportions tested to determine the most effective mixture.

Additionally, a char oven was built to heat resin-rich wood under anaerobic conditions. This process produced biochar and pine tar, the latter proving to be an excellent protective coating for wood. The pine tar offers a natural and durable solution for surface protection, reinforcing the effectiveness of this traditional method.

DIRECTED GROWTH

I researched the use of bioplastics mixed with nutrients and mycelium spores. I wanted to find out how this plastic could direct the growth. It also allows for molding the substrate into different shapes, where the plastic is slowly eaten by and replaced with mycelium while keeping the shape. Finally, I researched using bioplastic as glue to connect alive mycelium panels. That allows building large, single-piece and alive structures, as the glue is replaced by mycelium, thus connecting the mycelium panels to each other. Alive structures that have the potential to regenerate.

DIRECTED GROWTH

I researched the use of bioplastics mixed with nutrients and mycelium spores. I wanted to find out how this plastic could direct the growth. It also allows for molding the substrate into different shapes, where the plastic is slowly eaten by and replaced with mycelium while keeping the shape. Finally, I researched using bioplastic as glue to connect alive mycelium panels. That allows building large, single-piece and alive structures, as the glue is replaced by mycelium, thus connecting the mycelium panels to each other. Alive structures that have the potential to regenerate.

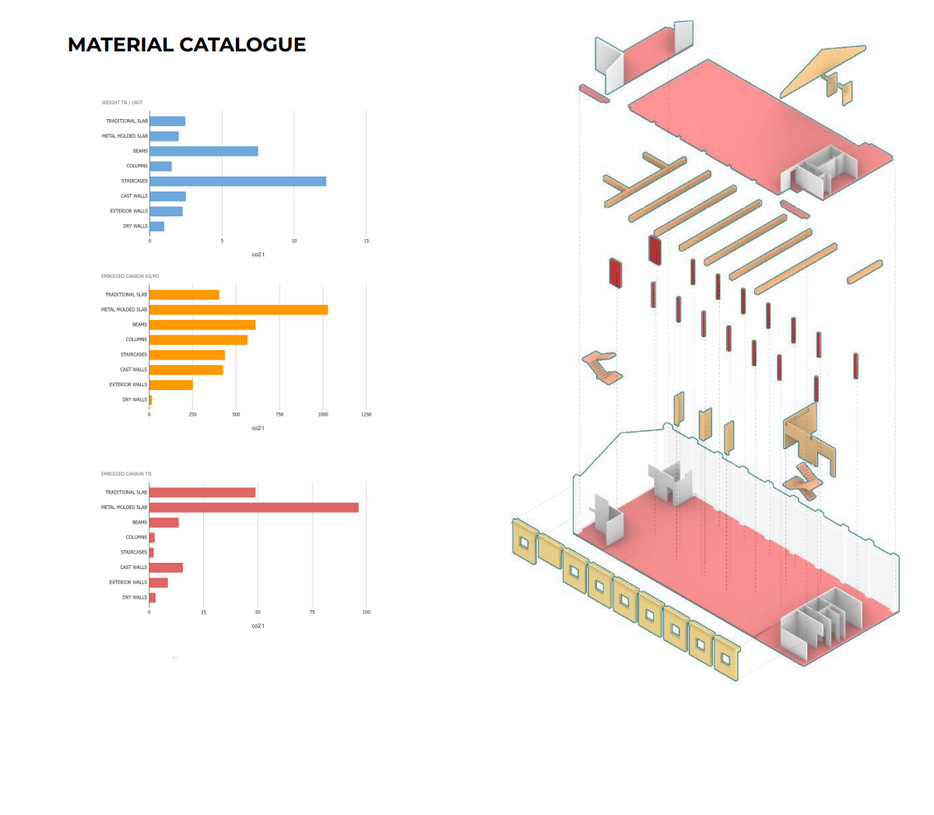

Circular Concret

Circular Concrete explores strategies to reclaim and recycle concrete from buildings set for demolition. By "dismantling with intention," materials are categorized and added to an online material bank, where users can request customized cuts or access standardized pieces commonly used in the industry. An ecological feasibility check evaluates transport energy and carbon emissions, showing how far materials can be moved while remaining more sustainable than new production. Leftover materials that cannot be reused directly are upcycled into new products, ensuring minimal waste and maximum resource efficiency.